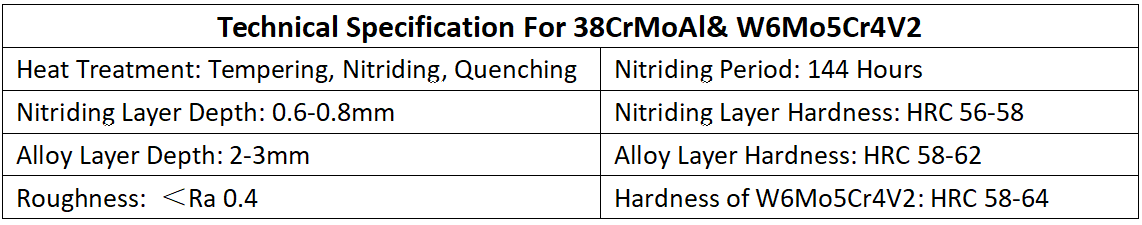

1. W6Mo5Cr4V2 (M2, S652) will be used for producing screw elements, after heat treatment, it will have excellent abrasive resistance.

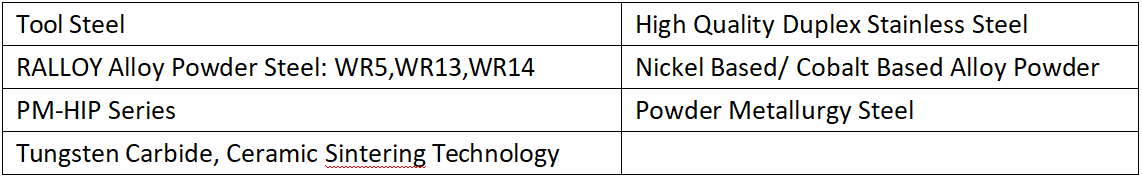

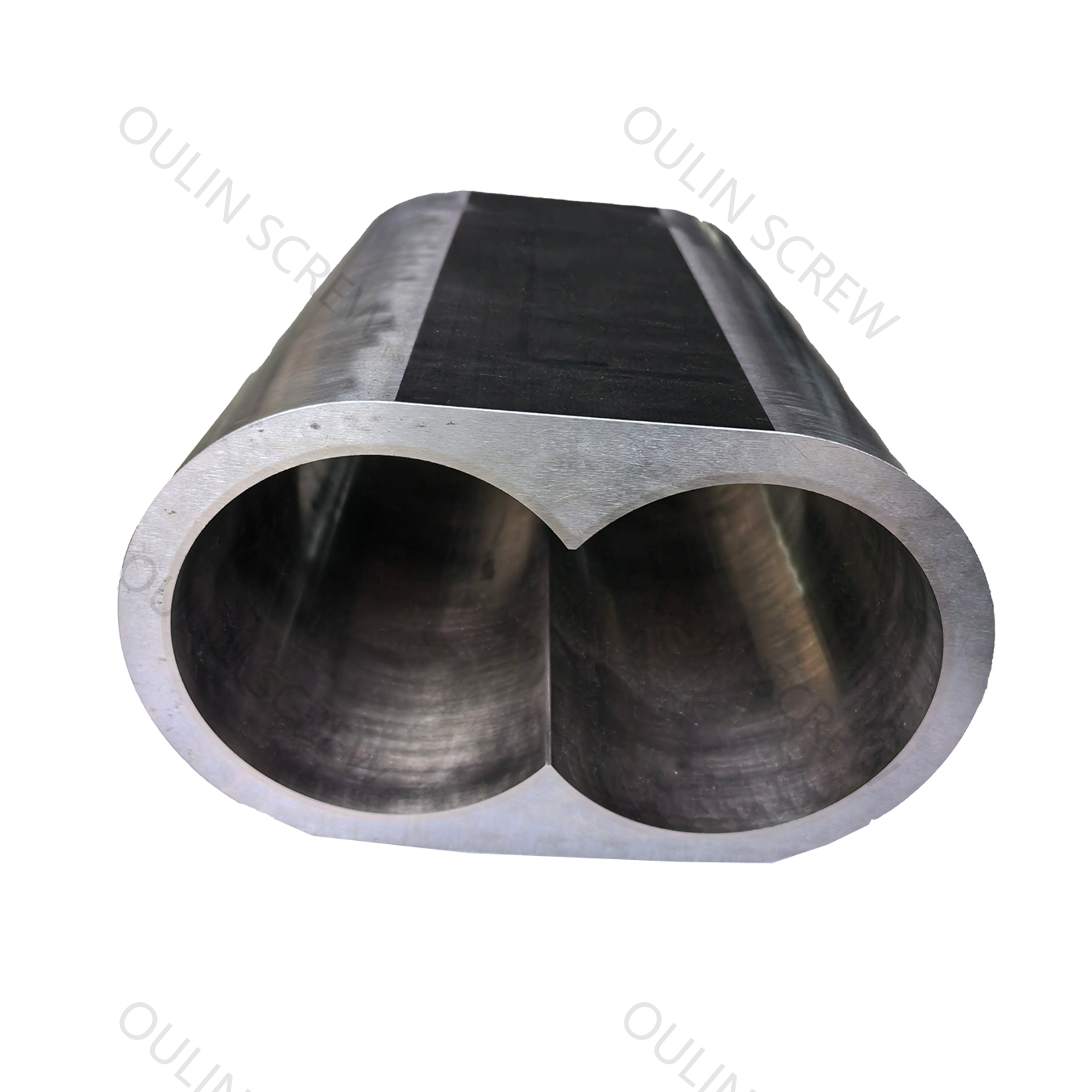

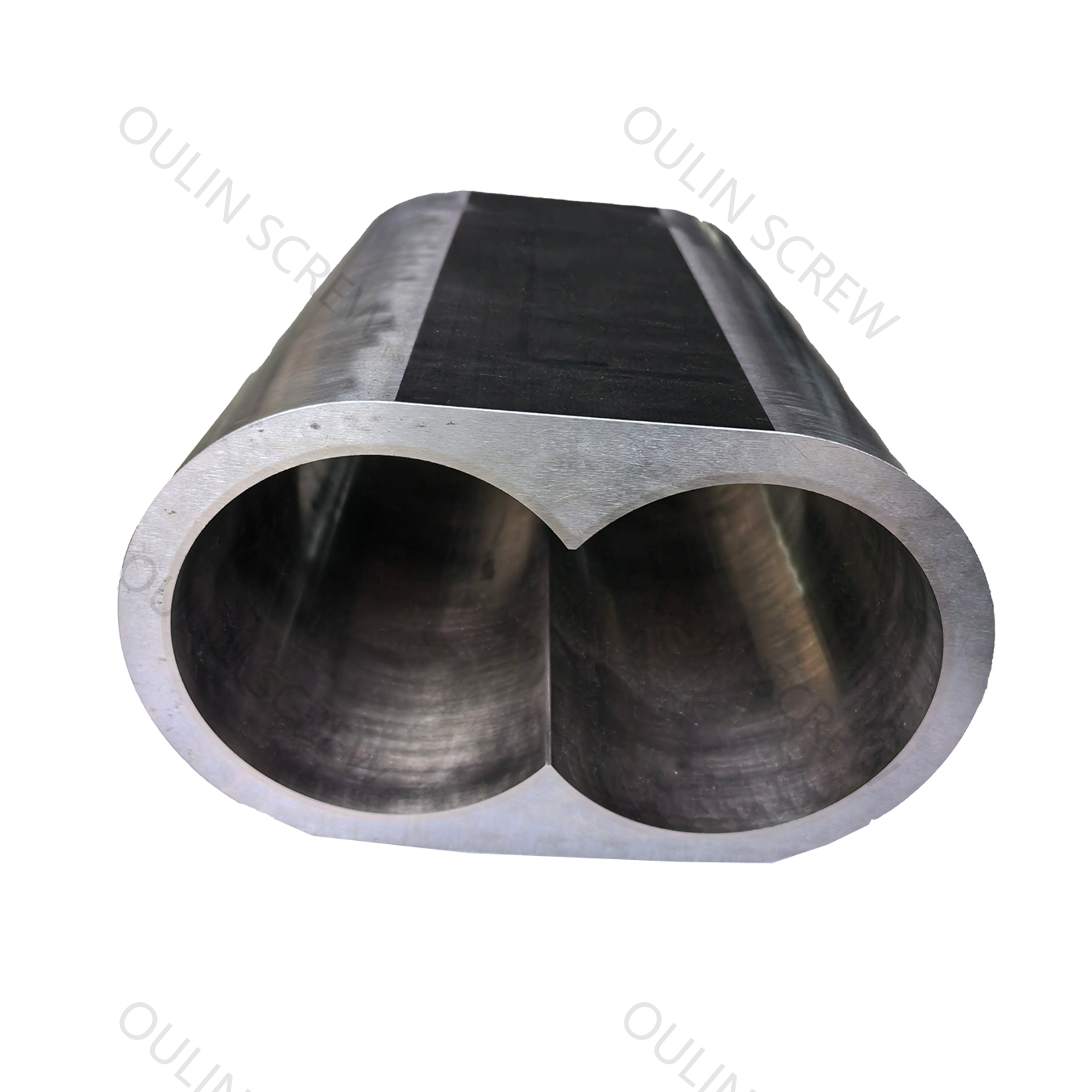

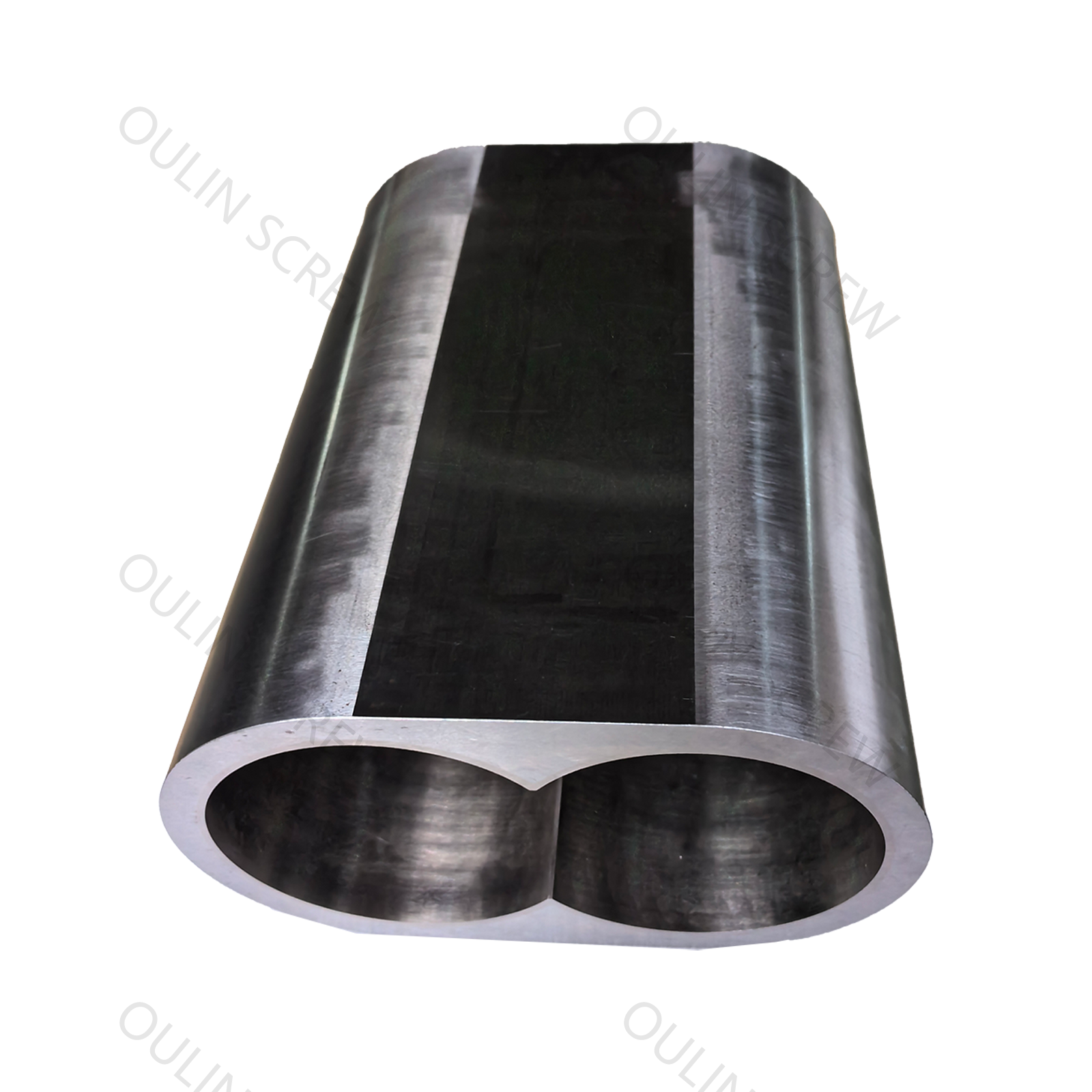

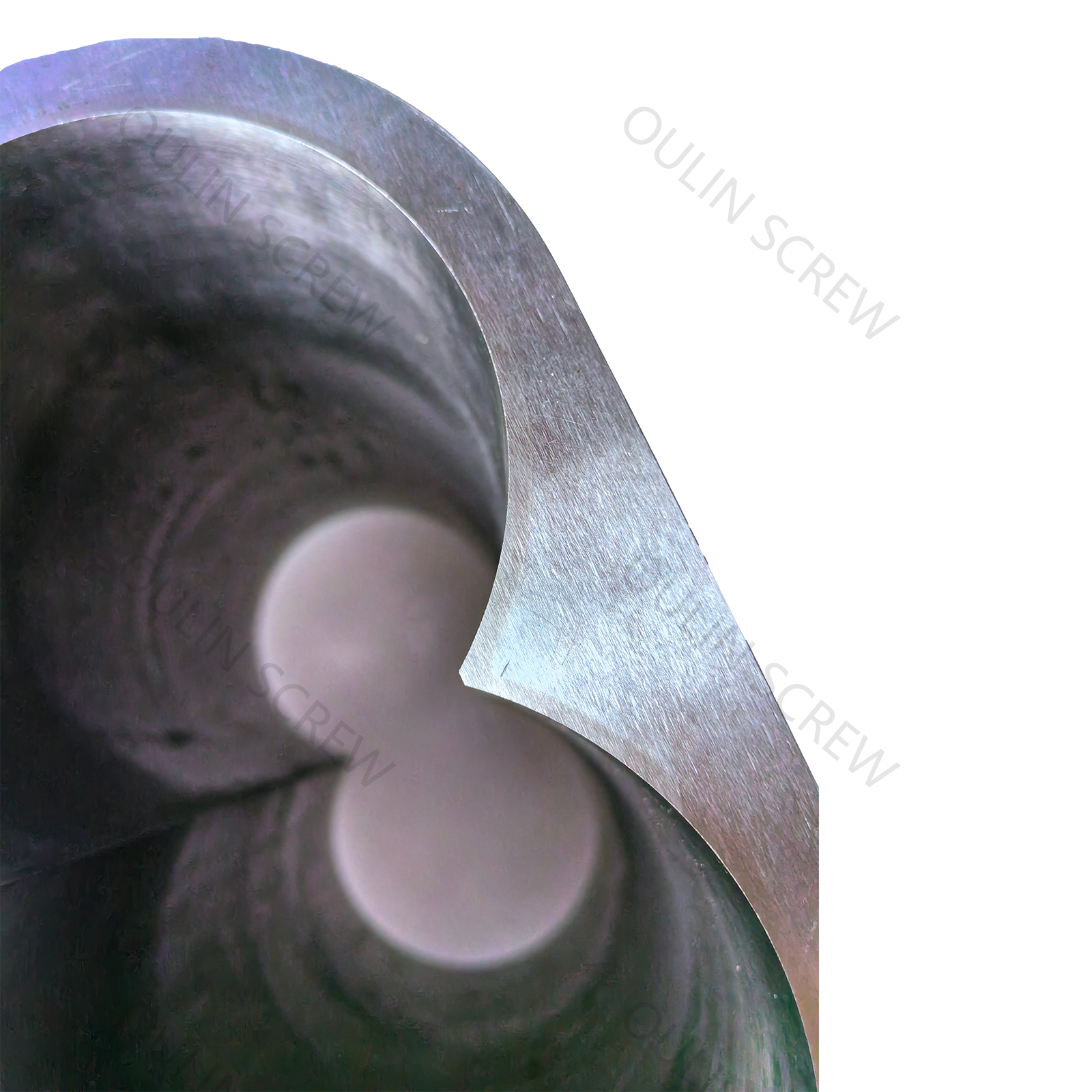

2. 38CrMoAl (41CrAlMo7) will be used for producing segmented barrel, after heat treatment, it will have good abrasive resistance, medium corrosive resistance.

3. 40CrNiMoV will be used for producing core shafts, after heat treatment, it will have good torque resistance.

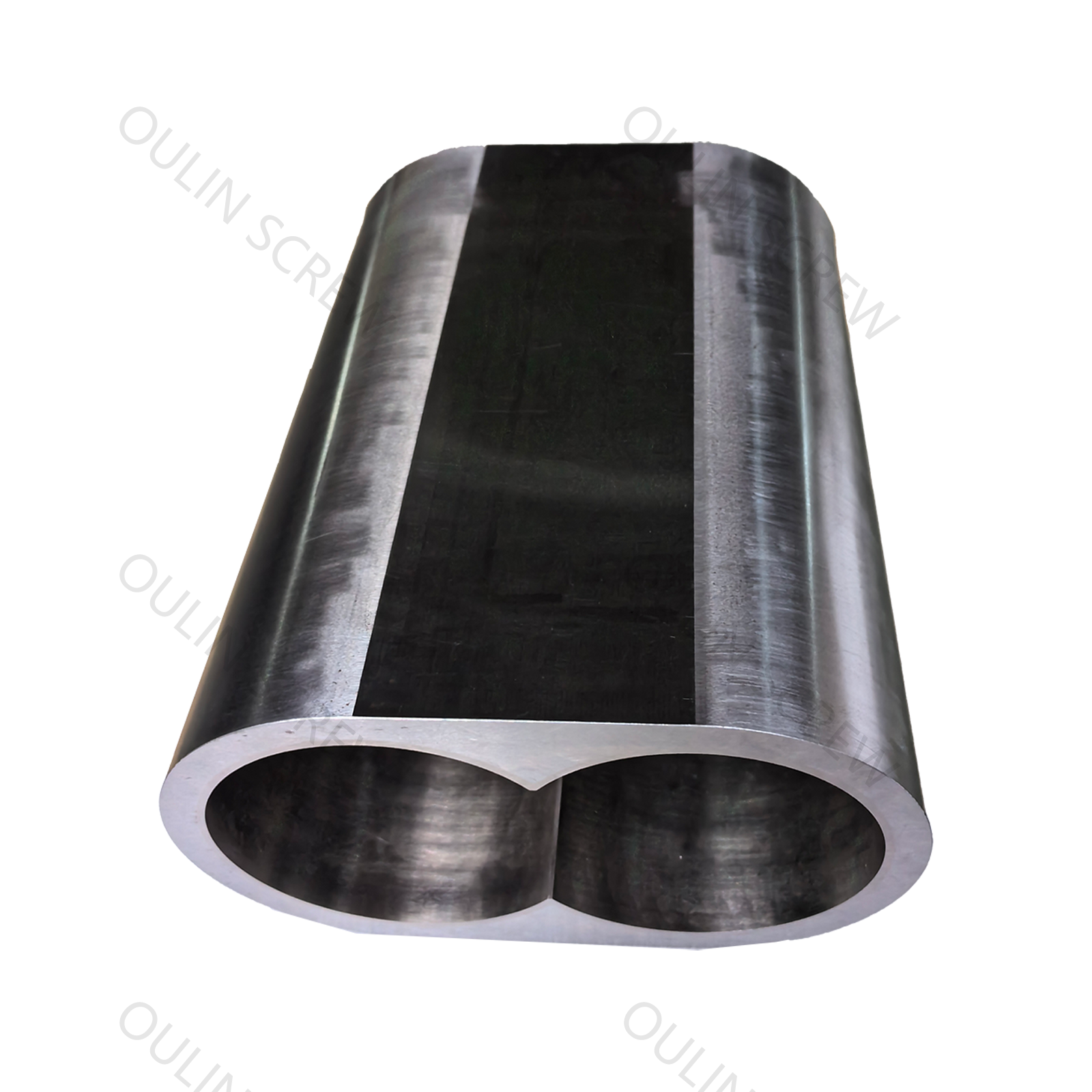

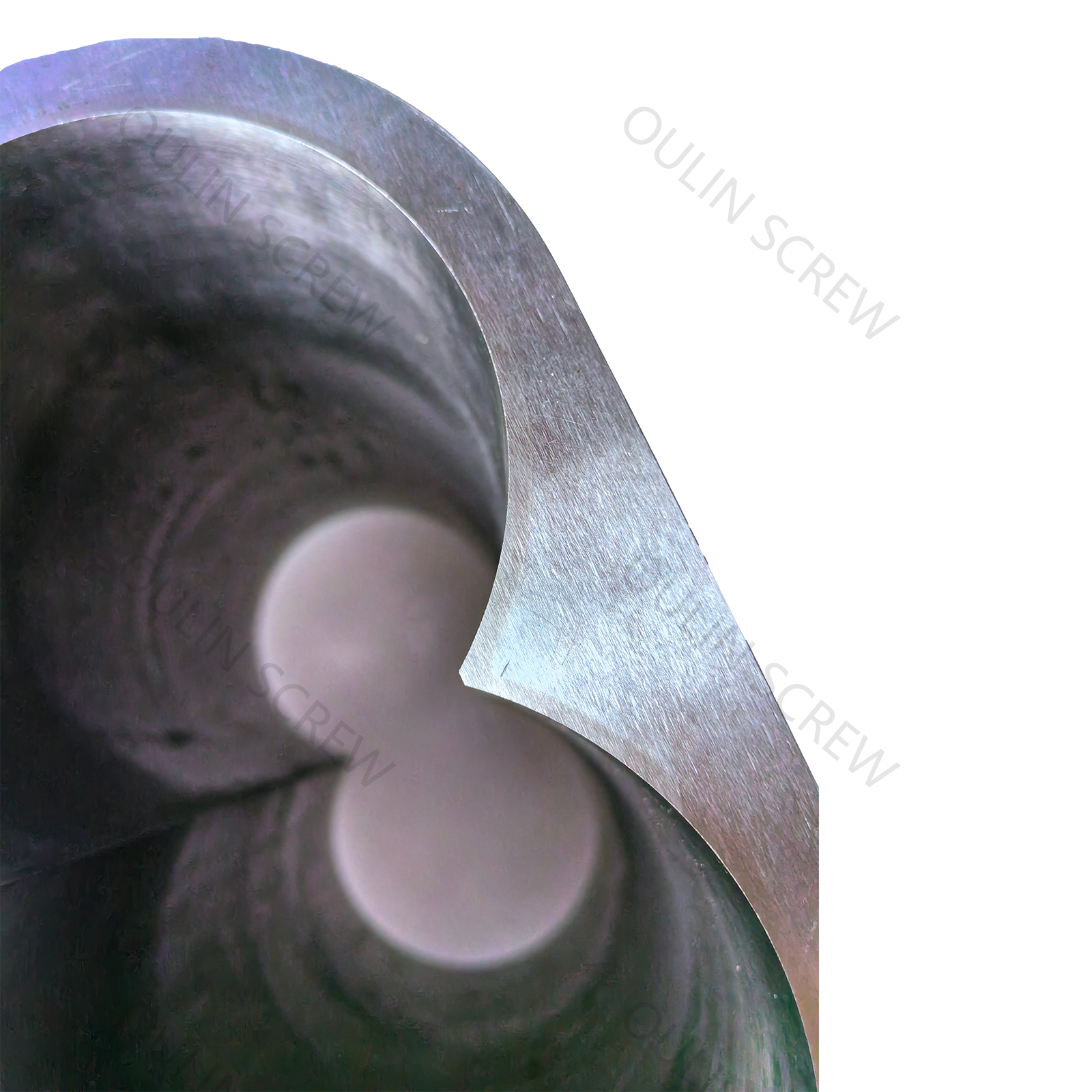

4. For higher quality requirement, better steel can be used for making screw elements, barrel can be bimetallic quality.

1. W6Mo5Cr4V2 (M2, S652) will be used for producing screw elements, after heat treatment, it will have excellent abrasive resistance.

2. 38CrMoAl (41CrAlMo7) will be used for producing segmented barrel, after heat treatment, it will have good abrasive resistance, medium corrosive resistance.

3. 40CrNiMoV will be used for producing core shafts, after heat treatment, it will have good torque resistance.

4. For higher quality requirement, better steel can be used for making screw elements, barrel can be bimetallic quality.

Furthermore, better steel or production technical can be used for higher quality requirement: